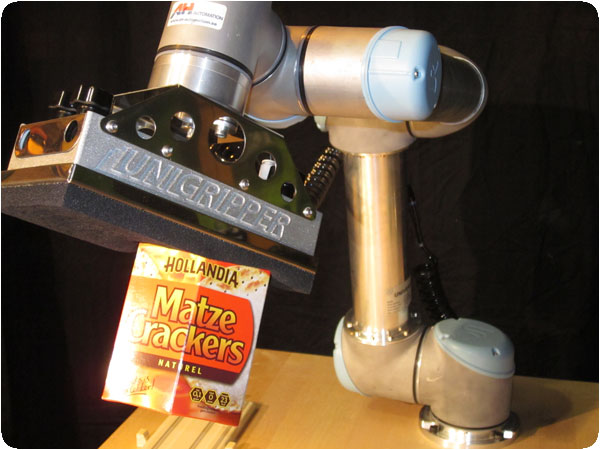

UniGripper Vacuum Grippers

UniGripper is the brand of the world leading lifting tools manufactured by Tepro Machine & Pac System in Sweden. Below is a short description of the UniGripper product program. For more information, feel free to navigate through our English web page on the menu above or contact your UniGripper distributor, contact information at the bottom of the page.

UniGripper's Function

We manufactured our first UniGripper tool in 1997 after the valve technology that most UniGrippers are based on had been patented. The UniGripper valve technology is the enabler for what we refer to as Intelligent Vacuum: a gripper head that automatically senses where the items to be lifted are located and focuses the vacuum force to the items, irrespectively if the entire or only a small part of the gripper is covered.

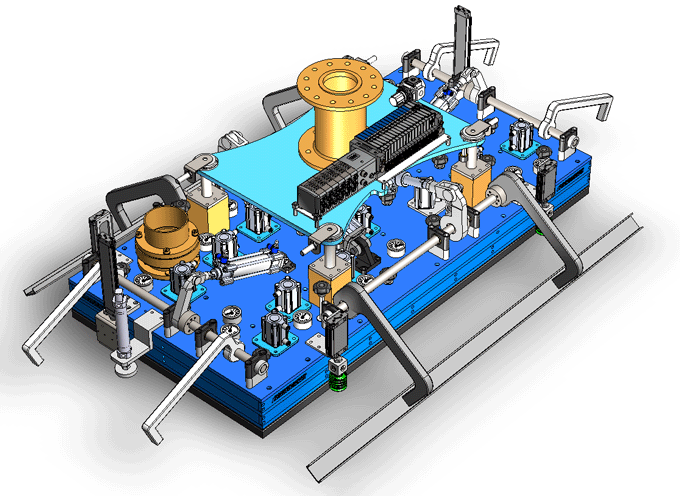

UniGripper consists of two plates assembled on a common frame. The top plate is equipped with a vacuum source, assembly holes or robot connector and various accessories depending on application. The bottom plate has a hole pattern where each hole includes a UniGripper valve. Onto the bottom plate is a foam carrier attached, on which the suction foam is glued. The suction foam creates an air-tight seal between the items to be lifted and the UniGripper and thus enables vacuum to be created. Inside the foam carrier is in many cases a filter cassette that efficiently prevents intrusion of dust and dirt into the UniGripper and the vacuum generator. The foam carrier is easy to dissemble and reassemble in order simplify and speed up maintenance. Depending on application we customize the hole pattern and material of the suction foam to create an optimized tools for products to be handled.

Product Program

Since the start UniGripper as evolved into a complete range of lifting tool for all kinds of products and materials that need to be handled.

Sedan starten har UniGripper utvecklats till komplett produktprogram av lyftverktyg för alla tänkbara produkter och material som behöver hanteras. Vi fortsätter kontinuerligt att utveckla UniGripper för nya tillämpningsområden och vår största styrka ligger i förmågan att ta fram ett lyftverktyg som är optimalt för varje hanteringssituation. Vi har anpassat ventiltekniken efter olika tillämpningsområden och erbjuder därtill ett brett program av tillbehör. På så sätt kan UniGripper bli mer än ett lyftverktyg; det är ett komplett verktyg som utför alla uppgifter som behövs för din automatiseringslösning.

UniGripper Customized

UniGripper Customized, is considered a benchmark in vacuum handling and comprises vacuum grippers in arbitrary shapes and sizes for customer-specific applications. Core values for UniGripper Customized are quality, flexibility and reliability in designs tailored for the customer's needs. The customizations are made with a number of different gripper types as a basis, which are presented below.

UniGripper Classic

This is a plain vacuum head where the size, valve pattern and suction foam is adjusted based on the products to be handled.

UniGripper MultiChamber

In this gripper type the gripper is divided into multiple zones or chambers where vacuum can be turned on and off individually. This enables several release positions of products picked up together. Used to speed up for example an automized palletization solution.

TimberGripper

TimberGripper is developed for the rough environment that handling of untreated wood implies.

TimberGripper is the natural choice when designing a new wood-handing vacuum system, and is also frequently used to upgrade and improve existing wood-handling systems.

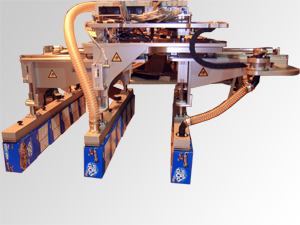

LayerGripper

For full layer handling, either palletizing, depallletizing or repalletizing. LayerGripper is available in a number of editions. Our most advanced edition, Edition 4, is specifically targeted for use on robots in distribution centers, combining low weight with the ability to lift bottles, cans etc. in boxes and trays, with or without shrink wrap and with large variation in height between products.

BagGripper

Vacuum gripper for everything from big bags to small pouches in both paper and plastics. BagGripper is the optimal solution for depalletizing where mechanical tools often fail. Can also be used speed up mechanical bag palletizing cells.

CoilGripper

The CoilGripper can handle coils, rolls and reels up to very high weights. For coils in metals, paper, plastic, fabrics, etc.

LightWeight Gripper

Produced in low-weight materials for applications where extra low weight is key. For low-payload robots or for very short cycle times with especially high accelerations.

HoverGripper

Our latest member in the Unigripper Customized family is HoverGripper for handling of full layers of thin-walled containers, that implode even at modest vacuum levels. Example of product to handle is a full layer of empty plastic cups.

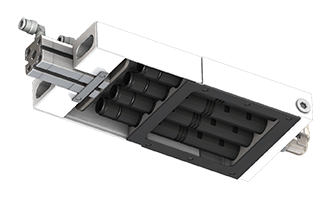

UniGripper Standard Module System

UniGripper Standard Module System (SMS) is our series of standardized vacuum grippers. UniGripper SMS is available in two widths, 80 and 120 mm, and in lengths up to 6 m.

UniGripper SMS is designed to allow multiple modules to be attached next to each other, thus creating a tool that is wider than 120 mm. Lengths 200, 300, 400, 600, 800, 1 000, 1 200 and 1 400 mm are available off the shelf to give extra short lead times for both new tools and spare parts.

For each length there are three standard valve patterns available to be used for different types of products. The SMS grippers can either be equipped with an internal vacuum source (venturi ejectors) or connected to an external vacuum source.

UniGripper Specialized Solutions

Due to the vast knowledge of product handling, the trust gained from our customers and delivered quality of existing projects, UniGripper is often approached by customers in need for innovative solutions to their complex and advanced handling projects. Innovation has a long tradition at UniGripper. Ever since we invented the UniGripper patented valve technology, we have improved and developed it further over the course of the years. This makes us the driving force not only innovating and creating new solutions for the most complex handling projects, but also in generating new technologies for material handling. Our goal is not only about finding a vacuum gripper solution for our customers. We strive to find the total solution for our customer, both in quality and efficiency. Whether it is vacuum or a combination of different types of product handling solution, UniGripper is the one stop shop for your handling needs.

Accessories

The UniGripper can be equipped with a many different accessories to ensure that your end-of-arm tool can perform all required tasks. Many accessories are part of our standard library, some of which are mentioned below. We also develop new accessories when such requirements arise.

- Pallet hooks for handling pallets. Primarily used in scenarios where the pallets are dirty and not suitable to get in contact with the foam pad.

- Suction cups for slip-sheet handling in those cases the suction plate is not designed to handle the slip sheets

- Floating attachment to make the UniGripper's vertical position flexible relative the robot attachment. Simplifies case where the height of product varies slightly or when a layer is not horizontally flat

- Robot adapter for easier attachment to the selected robot

- Air knives for removing excess dust or water on products when needed

- EcoCharger that boost the vacuum force while enabling a smaller power source

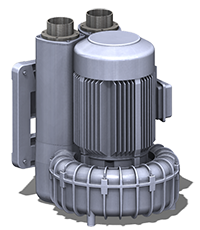

Vacuum Sources

An important part of the Unigripper system is the vacuum source that generates vacuum. Either through compressed air (ejectors) or by electricity (blowers/pumps). We naturally help selecting the most optimal vacuum source for each project and supply it with the UniGripper. We also have a wide range of accessories related to the installation of the vacuum source, to make your project run smoothly.